You’ve just discovered a gap in your desired market and you’re sketching the product you wish had existed months ago. Excitement is building, retailers are nibbling, and early testers are pushing you to launch faster.

But there’s a quieter worry lingering under the momentum.

You don’t know if your supply chain can survive its first real stress test.

That uncertainty is exactly where AI becomes a hidden advantage for small brands.

Simply Put, Yes It Does!

More young CPG companies are starting to treat AI not as a luxury, but as a practical way to keep risk under control while staying flexible.

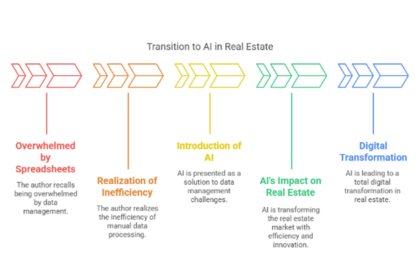

And in supply chain management, the shift isn’t theoretical. It’s happening because founders are reaching the limits of:

- Spreadsheets

- Guesswork

- Communication hurdles with vendors.

AI helps fill those gaps by spotting patterns and alerting teams to slow-forming problems, so brands get a chance to act before issues escalate.

AI and the Realities of Outsourced Manufacturing

Most startups don’t own production lines. They rely on co-packers, fillers, or shared manufacturing sites where they don’t control day-to-day operations. AI doesn’t change this model, but it strengthens it.

With the right tools, founders can evaluate partner performance, flag potential quality dips, and understand where capacity limits may appear.

Let’s consider an example.

In an in-depth guide from 2025, Power Brands outlines several contract manufacturing options for growing beverage brand visibility and market penetration. It highlights examples of flexible production setups and quality-focused processes.

Founders can use AI tools to assess if those setups and processes might work for their specific products and even the market they’re targeting.

When AI overlays these relationships, brands gain a clearer picture of what each partner can realistically deliver.

Why Early Stage Supply Chains Need AI Support

For many new brands, operations grow in unpredictable waves. One month demand stalls, the next month it leaps. Without a solid data foundation, it’s easy for teams to miss signals that would have made planning smoother.

A helpful view of this trend appears in Businesswire’s coverage of CPG companies investing in visibility and collaboration technology, which highlights a crucial finding.

Brands are looking for faster insights and tighter communication loops.

It’s a sign that reactive supply chains are gradually giving way to more predictive ones, and even new entrants are expected to keep pace.

How Startups Can Use AI to Reduce Risk Right Now

Below are several low-lift yet high-value applications that don’t require massive datasets.

- Demand sensing models that blend basic sales inputs with short-term trends

- Supplier risk scoring using simple historical patterns

- Computer vision checks on fill level and label alignment at partner facilities

- Lightweight digital twins to test production scenarios before a big order

Small wins like these build confidence early without overwhelming the team.

Improving Data Flow Between You and Your Partners

AI performs best when it has reliable inputs. The challenge is that suppliers and co packers rarely share data in a consistent format, and many don’t have sophisticated systems in place.

Startups can work around this by creating simple data sharing expectations through:

- Weekly production summaries,

- Quality snapshots,

- Or downtime notes.

Two or three clean data sources are often enough for basic models to offer meaningful insights.

This process also clarifies roles. When partners see how data helps reduce waste and prevent rework, they’re more willing to participate.

Building a Starter Tech Stack Without Overcomplicating It

Choosing tools can be stressful, but a lightweight approach works best for young brands.

Predictive Forecasting Tools

These platforms let founders combine sales patterns with retailer signals while keeping the interface simple. They cut down on overproduction and reduce the risk of stockouts during promotional spikes.

Logistics Visibility with Minimal Setup

In early 2025, Business Insider’s coverage of Swap’s logistics platform and its AI-driven optimization showed how even modest visibility tools can clarify inventory movements and lower fulfillment mistakes.

Transparency helps startups stay aligned with real-world market and operational constraints instead of assumptions.

Common Pitfalls When Implementing AI

New brands fall into avoidable traps like:

- Relying on too little data,

- Trusting early outputs too quickly,

- Adding tools faster than the team can absorb them.

Model drift is another issue, especially when marketing plans shift suddenly.

Pacing is key. You also want to let AI improve judgment, not override it. Human oversight keeps systems from drifting off course and ensures decisions remain grounded in context.

Preparing for a More Predictive Supply Chain

As brands gain more operational experience, their AI systems become:

- More accurate

- More helpful

- Easier to trust

With consistent data inputs and a clear workflow, even small companies can build early warning systems that alert them to disruptions before they happen.

The Future of AI in CPG Startup Logistics

AI is quickly becoming a practical tool for founders who want fewer surprises and more control. The brands that adopt it early will adapt faster as markets shift. For more ideas on improving operational efficiency, browse our latest articles.