From the second we get out of bed to the moment we come back home, IoT surrounds us. The benefits of these connected devices have not eluded most business verticals. Worldwide, organizations are leveraging IoT to improve quality, decrease costs, and more.

The Demand for IoT Devices is Exponential

According to IDC, by 2025, we can expect 41.6 billion electronics on the Internet of Things to be up and running. That’s roughly five devices per human, and this is just the beginning of overwhelming industry demand. No wonder the current investment in IoT devices is approaching $900 billion.

Unique Challenges Facing the IoT Industry

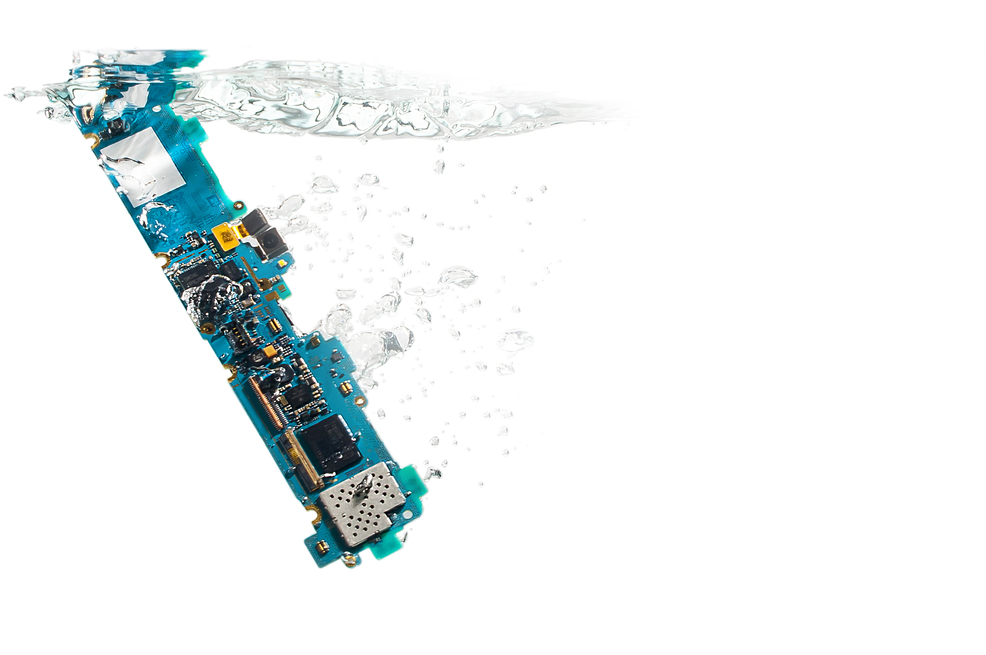

The uses of IoT are diverse, which means the environments you’ll find it in are just as varied. When exposed to the elements, simple conditions pose complex threats to IoT electronics. A drop of oil, the sweat of a user, or the humidity of tropical climates puts electronics in jeopardy.

IoT devices will be subject to rain, salt fog, gas emissions, and more. Simply put, if left unprotected, they will fail. These failures cause expensive repairs, downtime, and detriment to brand reputation. Malfunctions in mission-critical applications can have catastrophic results. One failure can put lives at risk.

Electronic Device Durability is No Longer Optional

With the advent of IoT taking electronics into wet and hazardous environments never before experienced by a PCB, industries quickly realize that protection against liquid and wet environments has gone from ‘nice to have’ to a necessity. The question remains, however, what is adequate protection?

One would look to industry standards as a guiding light, but quickly learn that current IP (Ingress Protection) Standards are limited in their scope of protection, not taking into account the diverse environments and liquids experienced by today’s IoT devices. For example, IP Standards are limited to new devices, only exposed to freshwater.

This lack of relevant and adequate standards leads to significant field failures and brand degradation as trust is lost in a product that is expected to function, period. Today’s IoT devices cannot afford to fail, which means they cannot afford not to be protected.

A Glimpse into the Next Generation of IoT Protection

Protection is needed, but what solution is best? What technology will hold up to today’s IoT environments? Older protection solutions have known limitations – mechanical seals can buckle with use, and thick acrylic coatings can exhibit voids where liquid can compromise.

In contrast, thin-film nano coating methods protect from the inside out. This unprecedented approach outperforms top industry IP standards. Devices with this protection survive both unforgiving conditions and the test of time.

Unparalleled protection is just one feature of innovative thin-film solutions. Other advantages include risk mitigation, cost avoidance, and incremental revenue creation. Consider the aftermath of a device failure after it has been subjected to the elements. The manufacturer now must deal with diagnostics, logistics, and repair costs. Meanwhile, customer satisfaction, retention, and brand reputation take a nosedive. All of this can be avoided with the proper application of thin-film protection solutions at the beginning.

What IoT Manufacturers Need to Know

OEMs, ODMs, and contract manufacturers need to understand the logistics of coating protection. When considering possible protection solution partners, these organizations should assess critical attributes in their protection providers, including supplier experience, domain knowledge, and industry expertise. A deep understanding of material science and innovative coating equipment is especially important.

HZO, the company that protects electronics from the most demanding environments with world-class nano coatings, has demonstrated proficiency when it comes to meeting these requisites. We have leveraged them all to deliver our trailblazing Spectrum of Protection™. Along this spectrum lies many proprietary coating solutions to create armor around sensitive circuitry. These solutions are specific to a wide variety of device designs.

The nano based materials in our Spectrum of Protection™ perform at a molecular level. This precision of protection offers more robust device durability and longevity, which leads to a decrease in product returns and an increase in customer satisfaction.

Our expertise and our customers’ needs drive our performance. We guide our clients through every step of the manufacturing process from the engineering consultation to quality checkpoints.

HZO delivers solutions ideal to the IoT industry. We protect delicate yet powerful components in ways other protection methods can’t. It is time to stop looking back and step into the next generation of IoT protection provided by HZO.