Most industrial and commercial processes have boilers as the heartbeat. They are a crucial part of production of heat, steam, and energy, whether it is manufacturing plants, power stations, refineries, or hospitals. But with time, boiler tubes are scaled, sooted, and other deposited, thereby decreasing efficiency, increasing the consumption, and decreasing the life of equipment.

Given that cleaning boiler tubes regularly is necessary to keep them operating optimally and to prevent the expensive downtime associated with this procedure, it’s necessary to get the right boiler tube cleaning system.

The Significance of Boiler Tube Cleaning

When using boilers, heat transfer surfaces are covered by a coating of scale, soot or slag. One of the thin coatings of these deposits can dramatically decrease efficiency causing the boiler to burn additional fuel to keep production levels high.

Failing to keep it clean will not only increase the cost of energy but also cause overheating and corrosion of tubes and eventual failure. The right boiler tube cleaning system will eliminate such contaminants and restore your system to its optimum heat transfer with a longer life of your equipment. Periodical cleaning also helps in adhering to environmental regulations through reduction of emission and reliability of the system.

Methods for Cleaning Boiler Tubes

Depending on the task at hand and the degree of contamination, you can choose from a number of different boiler tube cleaning systems. The first step in selecting the appropriate choice is to understand these possibilities.

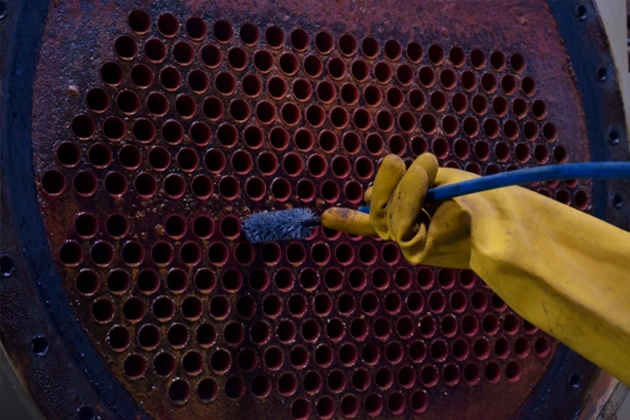

Mechanical (Rotary) Tube Cleaning System

These systems physically remove scale and soot from inside the tubes by means of revolving brushes, scrapers, or cutters that are driven by flexible shafts. If your facility values reliability, simplicity, and the absence of chemicals, these are the perfect choice for your firetube or water tube boiler.

Mechanical systems are simple to use and don’t break the bank. When routine hand cleaning is a component of the upkeep plan, they perform admirably. But they’re ideal for moderate fouling and might be more labor-intensive.

Air-Driven or Pneumatic Tube Cleaners

By forcing cleaning equipment down the tubes with compressed air, these systems are able to remove stubborn deposits. Large industrial boilers can benefit greatly from air-driven systems due to their power, portability, and efficiency. On top of being good in removing dried soot and loose scale, they also reduce operator fatigue.

Water Jet (Hydro-Blasting) Systems

For severely clogged tubes, one of the best options is a high-pressure water-jet cleaning device. To remove stubborn scale and corrosion from tubes, they use high-pressure water streams that are gentle on the surface. Industrial boilers, WHR units, and power plants of a certain size are perfect candidates for hydro-blasting systems.

Due to the enormous pressures involved, these systems necessitate trained operators and appropriate safety precautions, notwithstanding their great efficiency. They produce wastewater as well, which could necessitate some sort of wastewater treatment or disposal strategy.

Chemical Cleaning Systems

Boiler tubes are subjected to chemical cleaning processes that disintegrate deposits like scale and rust by means of the circulation of specifically prepared solutions. When mechanical or water-jet methods fail to completely remove mineral buildup, this procedure is thorough and effective.

To maintain environmental compliance and protect the boiler material, chemical cleaning must be handled with caution. It’s more commonly utilized as an additional thorough cleaning approach than for routine maintenance.

Soot Blowers (Online Cleaning Systems)

Soot blowers offer online, automated cleaning for big power plants or continuous-process operations. While the boiler is running, they flush out the soot with jets of steam, air, or water. This helps keep operations running smoothly in between shutdowns and reduces downtime.

Important Things to Think About When Picking a Boiler Tube Cleaning System

To choose the best boiler tube cleaning system, you need to think about a number of things related to your facility’s operations, maintenance habits, and budget. Learn more here https://www.power-eng.com/coal/advances-in-boiler-cleaning-technology/.

The Nature and Size of the Boiler

There are different ways to clean different boilers. For example, spinning or pneumatic cleaners are often used on firetube boilers. Watertube or high-capacity boilers, on the other hand, can benefit from hydro-blasting or soot blower systems. The best fit will depend on your boiler’s shape, tube diameter, and how easy it is to get to.

Deposit Types

Your choice will depend a lot on the type of fouling, like whether it’s hard mineral scale, soft soot, or sticky material. Chemical or hydro-blasting methods are better for hard, thick scaling, while mechanical systems work well for loose or mild buildup.

Frequency of Cleaning

Automated or quick-deployment systems like pneumatic cleaners or soot fans may help facilities that need to be cleaned often because of the type of fuel used or the way they are used. Chemical or hydro-blasting methods may be better for deep cleaning things only once in a while.

Workplace Health and Safety Needs

Think about how much work and skill are needed to run the system. Cleaning systems that are done by hand might need more workers, while mechanical systems need less work from people but might cost more at first. Always make sure that the method you choose follows safety rules and keeps you as far away from heat, chemicals, and high pressure as possible.