In today’s world of welding and construction, achieving precision is not a luxury but a minimum requirement. Regardless of the scope of the project, professionals who work in these fields now insist on only using tools that help them achieve the best of precision while also increasing efficiency and productivity.

When it comes to projects that require working with all kinds of pipes, professionals now depend on orbital saws to achieve this level of precision and productivity. So, in this article, we will be looking at three of the top uses to which orbital saws are put in the field of welding and construction. This will give you a better understanding of why this tool is in high demand in these fields.

What Are Orbital Pipe Saws?

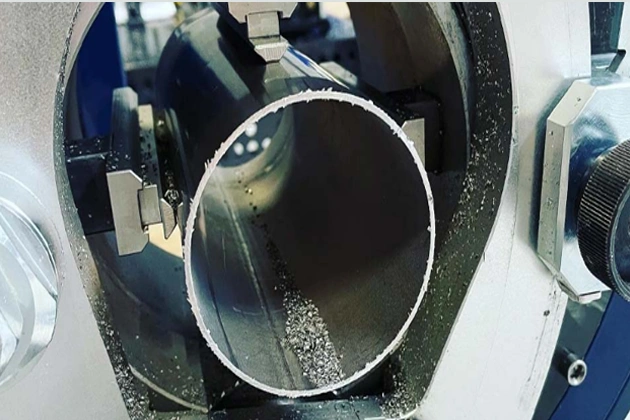

Orbital pipe saws are specialized cutting tools employed in welding and construction. These tools use a special cutting method that involves clamping onto the pipe and then using a rotating motion to cut the pipe from its outer circumference. This method ensures that the cut is burr-free, clean and square.

It is effectively used for cutting carbon steel, stainless steel, and other alloys. Because it does not generate so much heat energy while cutting, the integrity of the cut material is largely maintained. This efficiency and precision has made it quite popular in the welding and construction industries.

3 Top Uses for Orbital Pipe Saws in Welding and Construction

Now, let’s look at three top uses for this tool in welding and construction.

1. Precision Pipe Cutting

Precision cutting is one of the most critical uses that orbital pipe saws are put to in the construction and welding field. It is critical in certain industries, including those that require high-purity levels like food and beverage processing, pharmaceuticals, semiconductor manufacturing, and biotechnology. These industries require pipe systems without rough edges, contamination or weld defects.

Another example is the oil and gas industry where hundreds of miles of pipeline is laid to carry these fluids. The pipes used in these cases need to be precisely cut so they can be welded perfectly to reduce any chances of leaks at the weld points.

In these examples, orbital saws produce pipes that are burr-free and with perfect square cuts. Pipes with these features can be easily fit together and welded perfectly, reducing the presence of impurities within the pipe and increasing structural integrity around the welded joints.

Here are some features that make orbital saws excel in these functions.

- Consistent Precision: No matter how many pipes an orbital saw cuts, it will maintain the same level of precision. As a result of this precision, joining each cut end with the other is easy because the gaps are reduced so when it’s time to weld, it is straightforward and full-proof.

- Cold Cutting: Previously, when pipes are cut, the cutting process generates a lot of heat which can affect the integrity of the material. This is not the case with orbital saws as they cut without generating considerable heat. This means that the integrity of the cut material is maintained after the cut. You can read how heat affects materials during cutting here.

- Reduced Risk of Contamination: Contaminants like filings, oil, and debris are reduced in this type of cutting. This is what makes it ideal for some of the industries we mentioned above.

2. Cutting Thick-Walled Pipes and Exotic Alloys

Other than the standard carbon steel pipes, there are industries that make use of pipes made from other materials that are more resilient. Examples include power generation, oil rigs, aerospace and petrochemical plants. These industries make use of materials that offer impressive heat resistance, exceptional strength and strong resistance to corrosion.

Some of these materials include titanium, duplex stainless steel, Inconel and hastelloy. Because these types of materials cannot be easily cut with the regular cutting tools, they rely on orbital pipe saws for such operations. Orbital saws are great for this because of the following features:

- Low Heat Performance: Its operation is described as cold-cutting because there is no heat buildup during the cutting process. This means that cutting can continue as long as required without the material being compromised structurally.

- Precision Blades: The blades are specially designed to efficiently cut through most types of materials without the blade failing. The cutting process will also not result in any significant wear.

- Smooth Finish: Because of the way it cuts with precision, errors are reduced to the barest minimum and the finishing is smooth. This ensures that there is no waste so the material is utilized fully.

3. Fabrication and Installation of Industrial Process Piping

Industrial process piping requires the use of pipes that can handle the pressure exerted by the gases or liquids being transported. To this end, aside from the use of special material for the pipes, there is also the need for them to have durable welding so that these welded points do not become weak links.

Prior to welding, orbital saws are used in this process to achieve a number of things. These include:

- Accuracy and Precision: The accuracy and precision that orbital saws bring to the table ensures that there is little to no need for reworks. Remember that at this scale, reworks can be both expensive and time consuming.

- Speed: Given the scope of industrial projects such as these, the quantity of pipes to be cut will often be large. Using orbital saws, these pipes can be cut to the required length very quickly without compromising on precision. This ensures that projects are completed on time.

- Versatility: Regardless of the width or wall thickness of the pipes to be used, these saws can be used with ease. They will easily cut different sizes of pipes as required in the project. This increases efficiency, speed of completion and ease of work.

The above are just three examples of how orbital pipe saws are used in welding and construction. You can find out more about their uses here: https://www.linquip.com/.

Conclusion

Orbital pipe saws are changing the way that industries requiring precision pipe cuts now work. With their ability to cold-cut with precision and to do so repeatedly without error, greater efficiency is achieved and project deadlines are easily met.